Conveyor System for Transporting of Dirty Dishes – ALBA

Save with good design and automation

Custom manufacturing > Dish collection conveyor

A collection conveyor is used to collect and accumulate trays of dirty dishes in the catering area and transport them to the washing area to increase efficiency and reduce staffing requirements. It is ideal for schools, hospitals, corporate cafeterias or office centers.

The customer drops off the tray of dirty dishes at the collection area or sorts the trash into conveniently located receptacles. The staff stays directly at the dishwashing machine, removes food residue and places the dishes directly on the dishwasher belt or in the wash basket. There is no need to collect dirty dishes from the dining area.

The conveyor is made of AISI 304L stainless steel, is 50 cm wide and 90 cm high as standard. Its length is determined by the project. The movement of the trays with dishes is ensured by two longitudinal ropes, reinforced with cord with the possibility of user’s tightening. At the end of the conveyor there is a latch for detecting remaining dishes.

The conveyor control panel is located on the side of the conveyor with a rotary control for user adjustable speed 4-14m/min and a start/stop button. An emergency stop button is located on the staff and customer side.

Why have a dishwashing centre designed by Alba?

Exclusive design and bespoke construction

In collaboration with the architect and in accordance with his interior design of the canteen or dining room, we will prepare the first sketches and design layout proposals for the design of the dish collection conveyor. As a matter of course, the installation site is surveyed directly by our designers.

Professional design of the washing centre

We will design the complete solution for the washing centre, from the collection of dirty dishes, waste sorting, selection of the appropriate dishwasher to the subsequent storage of the dishes. We will efficiently plan the entire conveyor system taking into account the kitchen layout and staff requirements.

Delivery and installation of the collection conveyor

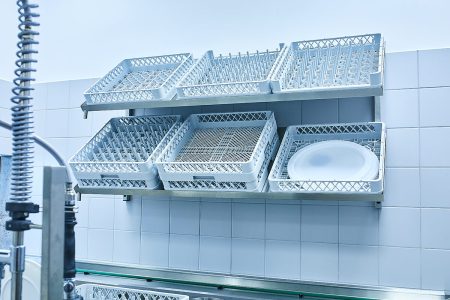

We will usually deliver and commission the conveyor within 4-8 weeks of a binding order. The delivery also includes a stacking trolley for tray collection. The design of the conveyor can also be supplemented with a sorting station and shelves for convenient collection and storage of baskets.

With available service and services

Despite the utmost reliability of our machines, the feeling of confidence that our technician is always on hand is priceless, and you can't do without regular service or warranty inspections either. Our technicians will inspect all ALBA machines in one visit.

For the washing centre of the Bořislavka canteen we have made a collection conveyor for trays with used dishes and a sorting station for 2 persons for the tunnel washer. This solution saves the work of an employee collecting dirty dishes from the restaurant area and at the same time increases the aesthetic value of the diners’ area, which is not degraded by racks with dirty dishes.

The double chord conveyor has infinitely adjustable speed on the operator’s side and consists of 3 straight sections, 2 90° turns and an end barrier guarding the full trays. The sorting station is equipped with a clean dishwasher basket tray, a folding shelf for sorting dishes and 2 waste openings for garbage.

For more information download our catalog

For more information about the dish collection conveyors, as well as the food preparation conveyors, please see our catalog. Including detailed technical specifications, descriptions and information about additional products we supply on request.